Points of view | Insights

PROFITABILITY PLAN: GENERATING BREAKTHROUGHS ABLE TO GALVANIZE A COST REDUCTION PROGRAMIn the European market, the difficult economic climate has prompted industrial firms to deploy innovative strategies to improve their operational performance and thus maintain their competitive advantage over players from emerging countries.

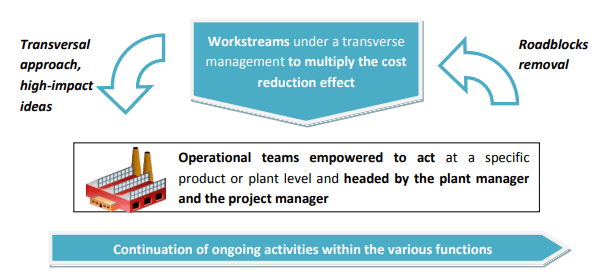

The improvement of the operating margin is notably due to global and significant reduction in costs for the company. To be global, the approach shall apply not only to all geographic entities but especially to all projects and to all the company’s functions. To be meaningful and complete, the company shall simultaneously mobilize its strengths and generate breakthrough ideas.

Four key success factors are to remember for a cost reduction program:

- An alignment of all projects and functions

- Ideas with high impacts

- Empowered teams with appropriate resources

- A governance to accelerate the implementation

Success factor 1: alignment of all projects and functions

To succeed in a global cost reduction program, all entities, projects, functions shall be mobilized. In an industrial environment, purchasing, engineering, manufacturing, logistics organizations will be encouraged to find leeway in their own scope in order to make progress towards a

common target set by the top management.

If the performance indicators can vary from one function to another, the cost reduction measurement indicator must be unique and shared by all functions. All costs must be taken into account. It may also be expressed in mass or per unit, depending on the context.

All functions are really involved including after-sales, marketing or quality, participating through their knowledge of the product, to its competitiveness.

This creates solidarity between the different stakeholders working together around a common target and it thus generates more transverse cost reductions (multifunction, multiproject, multi-site) with high impact for the company.

Success factor 2: high impact ideas

The level of the cost reduction has to do with the ability of the company to generate breakthroughs. The risk of a cost reduction program is to generate lots of ideas – sometimes thousands – with a very low average saving relative to the product – a few cents for a motor

vehicle for example.

To achieve remarkable reductions in costs, a primary source can come from cross-cutting initiatives defined on the field.

The second way – in fact compatible with the first one – is to focus the operational teams on ideas with strong business case ideally based on many benchmarks:

- ideas are prioritized according to their potential saving over the year and only the most promising are analysed,

- benchmarks from other industries for example to evaluate the competitiveness of internal / external costs but also from competitors as a source of ideas or even to raise awareness about the need for change… Very significant savings were observed with this type of benchmarks: significant product cost reduction, sometimes up to 50%, including on complex systems.

Success factor 3: empowered teams with appropriate resources

We discussed the need for an operational approach in the context of a cost reduction program. If such a program shall be established as a matter of priority for manufacturing teams in each of the industrial sites, operational teams, composed of representatives from each functions shall be empowered to act at a specific product or plant level where required. Several reasons are:

- Individual responsibility of plant managers and project managers with real decisionmaking power and the provision of a tool coherent and shared by all sites and functions give operational teams autonomy and flexibility conducive to the generation of

breakthroughs, - Operational teams sharing the cost reduction indicator with the rest of the company but not involved in the choice of product options and policy could feel that they have the decisions made by others imposed upon them when the cost impact would be negative.

This is obviously not conducive to their full mobilization.

Success factor 4: governance to accelerate the implementation

To be decisive in the success of this type of program and contrary to a centralized governance, the governance shall allow to bring the speed in the implementation of cost reduction actions. Indeed, in the absence of an accelerator at the top management level, the risk is high to see the deadlines for implementation of actions to lengthen and their dropout rates to increase. When the results are expected for the current year and the delays between approval and implementation exceed six months, the chances of program success become very weak…

Three particular directions in governance allow this acceleration:

- a batch approach: main work streams are defined at the program level. They may include:

– synergies between sites: multifunction, multi-project, multi-site. Take for example the case of several plants geographically close.

– product policy: multifunction and multi-site. Reducing the product diversity or content for example.

– performance of a function in particular: multi-project and multi-site. Improving industrial performance.

– synergies between several functions: multi-project and multi-function. Design-tocost of subcontracted parts involving engineering and procurement.

These work streams are in all cases under a transverse management in order to multiply the cost reduction effect. - short decision loops: different decision levels are defined by the governance. Each level has one or several steering committees (frequency: twice a month at a minimum). These steering committees can be part of the company organization and are not necessarily to dedicated to the program: project committee or management committee of a plant for example. Each of them permanently communicates with those of upper and lower level and the decision-making power at all these levels is known by all.

- escalation to the next level for arbitration: when decisions cannot be taken immediately, the issue is rose to the upper-level body that will arbitrate or forward itself to the next level. The highest level is controlled by the top management of the company, it makes key decisions related to the cost reduction process, affects the resources and removes roadblocks.

Conclusion

The combination of these four key success factors creates a continuous improvement dynamic:

Pagamon is a strategy and transformation consulting firm founded in 2013. We support major players in the industry, services and life sciences sectors in their search for balance. Helping them structure their strategic vision, transform their operational and/or digital model, and drive change. To support profitable, sustainable and responsible growth. As a committed player, Pagamon leads the Observatory of the Balanced Organization™, articulated around a “think tank” and an annual survey. In order to provide an innovative, sometimes offbeat, perspective on the strategic support of transformations to support the growth of companies.