Points of view | Insights

How to SET up AN ENGINEERING DESIGN PROCESS?Having a clear and shared approach is essential at the beginning of the pre-project phase.

How to strengthen the engineering design process right from the pre-project phase? How to integrate the good practices regarding the development from the upstream phase of the project?

By answering these questions, the customer makes room for manoeuvre, and then become quicker to react and able to make savings during the design phase. This reflection occupies a special place in the

complex goods industry, where every customer has its own demands and constraints and consequently, where every project is unique.

The stakes impose that we shouldn’t start all over at every new project, but also to handle the customers’ changes by locating the impacts right from the pre-project phase. It is then essential to qualify at best the technical needs with the design critical data. This also contributes to have a more precise calculation.

How to integrate these elements in the company processes in order to work on stronger design

processes? Two main ideas emerge:

- Having a frame for the new projects: the engineering design process of a complex

system allows to structure the transmission of know-how, skills and experience

feedbacks. - Anticipate the issues that will appear during the changes required by customers:

knowing all the links between the technical choices and keeping a trace of all the

decisions made during the project.

For complex designed products or for the “Manufacturing-to-order” industry, the engineering design process allows to lay the foundations of an organized conception. The impacts induced by the customers’ changes will be anticipated and the needs of each business involved in the development cycle will be collected.

Rule n°1: set up unchanging principles and definitions without ambiguity

The first condition to complete this type of project successfully is to fix rules and definitions shared by all. 3 principles have been retained :

- Starting from scratch:

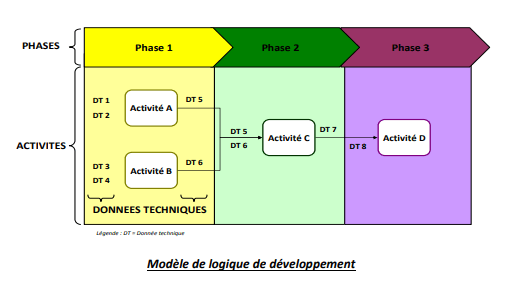

The engineering design process is a process, which needs to be built pretending starting from scratch. This condition is essential, mainly in sectors where the products are unique and where the globalization and standardization of products are lower than in mass production industries. (A tramway in Moscow is different from a subway in South Africa…) In order to have a such applicable process, we must focus on interfaces during the engineering phases, independently from the specific project constraints of the (planning, customers’ specificities, budget…). - String together the content and meaning of technical definitions:

The technical vocabulary used along the engineering process needs to be the same for all stakeholders. Some “phases” show the big steps of the project and must be common to all entities, some “activities” give information on the actions carried out by each business unit and finally, the “essential technical data” point out the technical parameters influencing the design. The naming of each part of information needs to be precise and explicit, in order to make it understandable by all the project’s players. - Being watchful on the information stitches:

Several levels of technical data exist, more or less detailed and specific. Thus, all players know and share the right level of information.

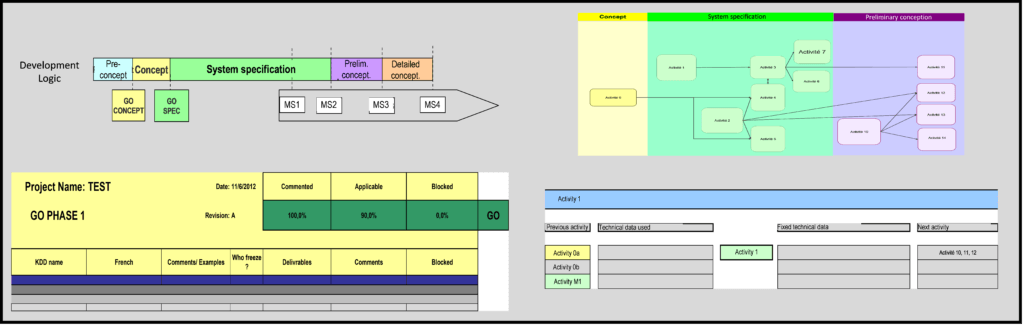

Rule n°2: fix the scope of the engineering design process

The second condition consists in delimiting precisely the studied perimeter. This perimeter is defined by the existence of different milestones which give rhythm to the development cycle. It also integrates the notion of interface between the different actors. It is essential to define the roles and responsibilities of the business units who intervene between each milestone and the associate technical data.

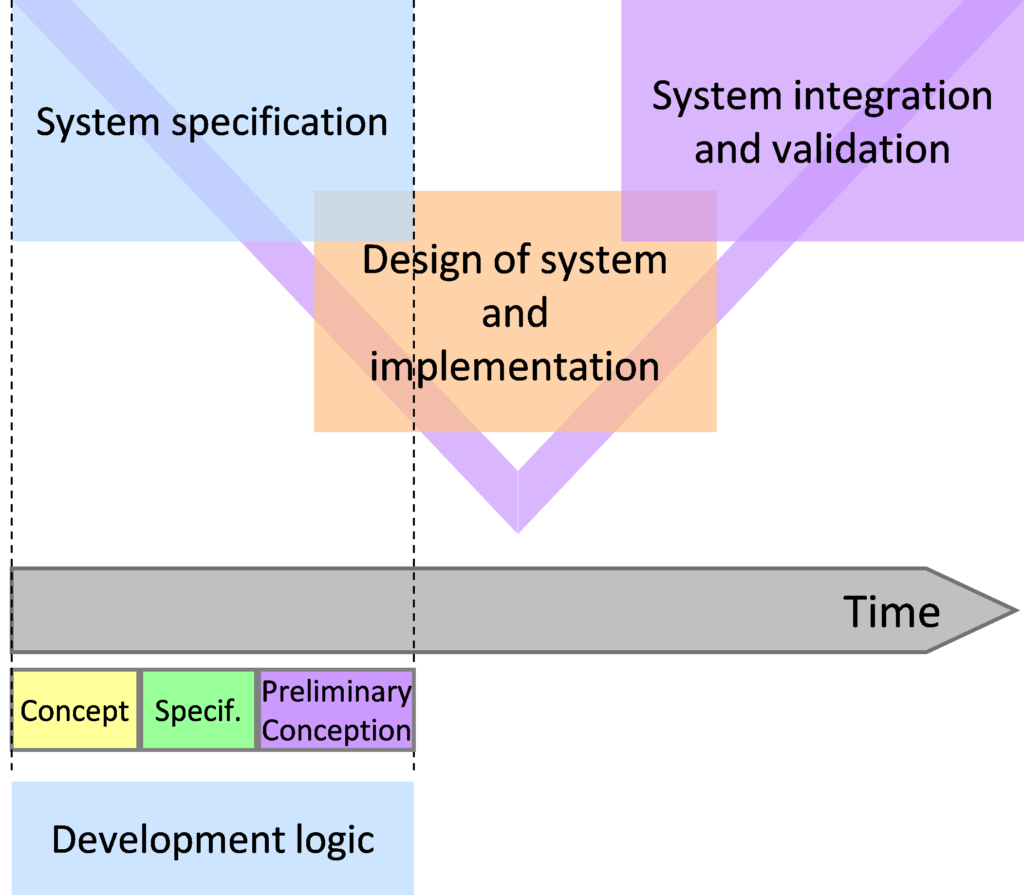

Delimit the big development phases – 3 major milestones:

- Systems development

- Integration

- Validation

This first step allows to set the beginning of the first “phase” and the end of the last one. In the Vshaped cycle process, the engineering design process starts at the beginning of studies and ends

before the detailed conception.

The engineering design process in a V-shaped cycle

Define the people involved in the project:

The business units that take part in the project need to be defined. Businesses and activities involved in the engineering design process must be identified. Then, for every chosen entity, it is essential to select cautiously the people to work with. These persons must have a global view of their actions while being as operational as possible.

Rule n°3: provide usable tools

The engineering design process brings many pieces of information. It is then very important to use complete, reliable and ergonomic tools allowing to treat all the collected information.

- Ergonomic tools that can be changed

- The transmission of treated information is the last step of the engineering design process.

- The spreading of information relies on structured and ergonomic tools ensuring users feedbacks.

- The structure of the tools has to make the update easy (fed by the different experience feedbacks).

Ergonomic check-lists that can be changed – Handbook collecting processes and technical data

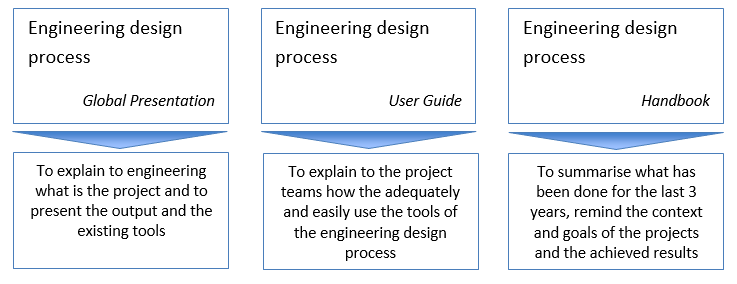

- Communication tools adapted to each population

The tools must rely on adapted supports in order to make their approach sustainable to the targeted population. Then, the change management articulate with 3 communication levels:- A general communication handbook for the entire company

- A global presentation for the people working on design

- A user mode for designers

Conclusion

An engineering design process allows to guarantee the achievement of several goals :

- Empowerment of all business units involved in the design: All decisions are now recorded, what involves the teams when they define design hypothesis.

- Known impacts when returning to a previous setting: When a change is required by the customer, the company is now able to know the design choices induced and consequently the actions that may be impacted. Then, we get a better assessment of additional time and costs induced by the changes.

- Sharing business units needs: The work carried out during the collection of information allows the different businesses to communicate their expectations and needs in terms of technical data.

The engineering design process is only the starting point of making design processes stronger. Many improvement lines are possible :

- Update of the first version an engineering plan: Experience feedbacks of project teams, procedures evolutions and improvement of the size grading of technical parameters may feed these updates.

- Broadening scope: The engineering design process may be implemented to new businesses or extended in the time cycle of the product.

- Coupling with planning management: The technical data may be used as a basis for project planning. Then, a standard estimate of costs and time will be integrated.

Pagamon is a strategy and transformation consulting firm founded in 2013. We support major players in the industry, services and life sciences sectors in their search for balance. Helping them structure their strategic vision, transform their operational and/or digital model, and drive change. To support profitable, sustainable and responsible growth. As a committed player, Pagamon leads the Observatory of the Balanced Organization™, articulated around a “think tank” and an annual survey. In order to provide an innovative, sometimes offbeat, perspective on the strategic support of transformations to support the growth of companies.

Pagamon is a strategy and transformation consulting firm founded in 2013. We support major players in the industry, services and life sciences sectors in their search for balance. Helping them structure their strategic vision, transform their operational and/or digital model, and drive change. To support profitable, sustainable and responsible growth. As a committed player, Pagamon leads the Observatory of the Balanced Organization™, articulated around a “think tank” and an annual survey. In order to provide an innovative, sometimes offbeat, perspective on the strategic support of transformations to support the growth of companies.